ESAB INDIA LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ESAB INDIA LTD.

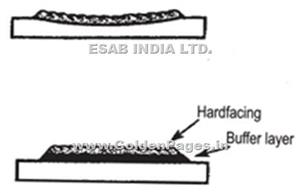

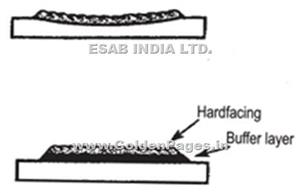

Buffering

Good bonding with the base material

Hydrogen-induced underbead cracking is avoided, even on preheated workpieces

Stress consequences are minimized

Effect of dilution is limited

Spalling in subsequent hard layers is avoided

Prevention of cracks or relief checks from the hardfaced layers running into the base material

Welding Cast Iron

Cast iron is an alloy of iron with a carbon content of 2-5%, silicon content of 1-3% and upto 1 % manganese. The major types of cast iron are

Grey cast iron

Nodular cast iron

Malleable cast iron

White cast iron

Cast iron has very low ductility, low strength and is very brittle. It is generally alloyed or heat-treated for improving these properties.

The high carbon content adversely affects the weldability of cast iron. Out of the grades mentioned above, white cast iron is considered unweldable for all practical purposes. The other types can be welded successfully with the consumables available.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.